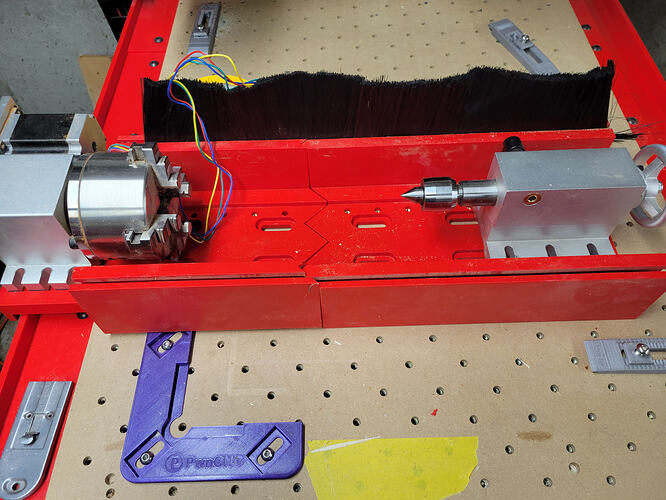

CNC built from kit circa 2010. Well used. Does not include water cooler, water cooled spindle, vrf, dust boot or rapid change atc in first picture. Includes rotary attachment with 3d printed jig. Includes porter cable 690 with dust boot and various collets. Includes mach 3 running on widows xp computer. Includes video camera used for finding corners/edges. Includes tool height setter from pwncnc. Includes usb pendent. Includes monitor. Includes stand if you want it. Electronics are gecko g540 based they work but are in sad shape. Single Y axis. Nema 23. 20 miles west of Boston MA. Will not ship. Needs to be gone by early February.

Maybe a STEM (Science, Technology, Engineering and Math) program at a local school would love to have it?

What I meant when I said the electronics are in sad shape was that they are not working as I would like, not that they are not working. The machine is currently working, as in all the motors work and it cuts what I program. The rapid change (not included) changes tools, and the spindle control (pwncnc spindle not included) works as well. The issues with the electronics are that when I added the spindle, the rapid change atc , and another tool height setter for the rapid change I had to expand the smooth stepper with expansion boards. Some of the input/output ports of the smooth stepper and the gecko g540 are not working as I expect them to (broken?). I had plans for these ports (such as detecting the dust boot is on). The “improvements” also added what appears to be a lot of noise into the system and as such I had to increase the efforts of the debounce circuitry. This led me to have to lower the speeds of the homing, and tool height setting code. Also the circuit I added to display the spindle speed has stopped working. In addition the spindle speed as controlled by the g540 wasn’t all that close to reality, I improved it greatly with a mapping file in mach 3 but it still was off by 5% at times. There are also some smooth stepper issues that show up at times of high static electricity (when I vacuum dust off the 3d printed jigs and move the spindle near them the smooth stepper throws some error). I suspect a grounding issue. In the end in order to get everything I wanted I was going to have to spend a lot of time or replace the g540/smooth stepper. Couple that with the frustration of trying to align the 4th axis and I decided that I wasn’t getting much enjoyment out of it. I decided to replace the machine with an avid 4x3 with a rotary.

HarryO interested in CNC contact me at 6037900479 if still have it?

Hi Paul - looks like I’m late to the game but if the unit is still available my son and I would love to give it some TLC and put it to work. We can pay for any shipping and handling.

Thanks!

Nick

602-403-5573

So it is still available but I have no idea how I would ship it. I suspect that shipping would cost more than it is worth. I will keep you in mind if no one local comes forward.

The first project it made was an electric guitar with my son.

https://youtu.be/9jEFcPvBkuc?si=Or8XTXHLn9JZBRT4

Paul

Wow that is awesome!

Sounds good – let me know and we can help figure it out too.

Cheers,

Nick

The item has been sold. It is no longer available.