should the laser be going to safe z after every line of code? All that up and down seems like it add a lot of time to the cut.

It should not be doing that.

What are you using to generate the g code? The Vectric laser module won’t do that.

If you’re trying to run g code generated for routing (and setting the rpm from 0-100 for laser power) you still need to set your safe heights very very low to avoid this.

My recommendation: use the laser module.

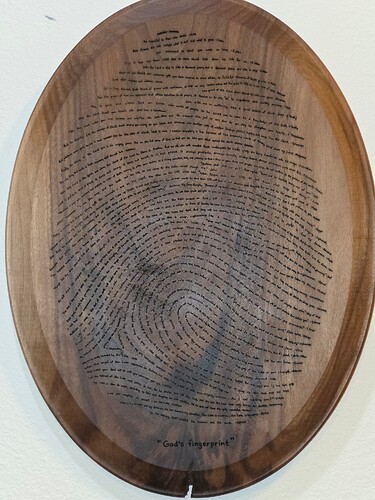

Yes I was using the vetric laser module for gcode, I contacted Jim and he sent me a PP that fixed the issue. The item pictured was taking 4hrs to laze and now it is down to 2hrs,

Yeah Jim!!

thanks.

bs

Odd that the laser module was producing g code that had lifts in it.. it shouldn’t have done that.

Awesome project, may I ask where you got the vector file from?

I scanned it from a piece that was bought on vacation. Pretty good idea. Right?

It worked well from the picture.

Yes I have made a few of them

I could have sworn Vectric fixed that a while back, but I just did a couple test cases on Vcarve pro 12.5, and it is definitely generating a safe Z lift on every rapid move if I use the stock AVID pp. I didn’t notice it before because I use a modified pp that takes out all but the first rapid Z. Thats the one I gave to Brian to try.

12.0 does the same thing too.

Ahhh, so we’re talking about a lift between operations, not on a group of vectors.

To avoid this you can make your Z lift .0001 and the it effectively won’t lift (but still will lift for rapids at the start and end of the job)

When you do that you really have to remember to change it back again for the next spindle job because it will remember this setting for the next job and drag your end mill across the surface.