Ah yes, retracting tool setter… and a camera in your dust manifold! How sweet it is! ![]()

True story;

A guy from Georgia built a cool thingy. Everybody wanted one of these thingies for themselves so he worked real hard to make it a kit. Cost him 10s of thousands of dollars to develop and nearly 3 years.

The day came to start getting his suppliers to commit to production. All of the suppliers were happy to help and gave this guy from Georgia their complete support… except for one.

This one “supplier” never answered a single email. Never returned a single phone call. Over the course of a year, never once reached out.

The part this company makes turns out to be the single most expensive and complex part in the kit.

But now this guy has a choice, does he keep begging this company for attention and commitment or does he go through another 3 to 6 months to design around something similar?

The cost will “only be a few more thousand” and multiple months.

![]()

My advice to this dude is design around something that is common, off the shelf and already in mass production from multiple suppliers. We’ll see if he goes bankrupt before he gets this thing out… ![]()

I’m for hoping this story to have a happy ending…

@djdelorie I think I am developing your sticky tool issue. The first tool of the day take a moment longer and pops out with some force.

[EDIT: Video was move to the correct channel ]

Try a bit of this:

I wonder though if the stickiness might be made worse by debris in the taper? Neither of us has an air-clean setup for the tapers we install.

Or the spindle warmup routine isn’t warming it up enough.

I leave the vacuum on during the tool change and that seems to keep the dust from sticking to the taper. As the tool holder is inserted the air flowing out of the case also seems to keep dust from being caught in there. I do check it once a week and haven’t seen anything stuck up in there.

I also do the new warmup routine. It takes about 14 minutes or so and I make sure its at least 90 to 95 F before starting.

So where do I put this stuff? Just hose it down? Put some behind my ears for good luck ![]()

Thin coat on one of the tapers, then do a bunch of insert/remove cycles on that spindle. Or thin coat inside the taper. When I did mine, I followed it with a mostly-wipe of a dry paper towel. the tiny layer that’s left is supposed to keep the tool from sticking, or so say the folks at cncdepot.

Also, if the snag is after taper release but before drawbar release (i.e. if it drops out of the taper but you have to force it the rest of the way out) you need the drawbar cleaning procedure - empty spindle, slowest speed, spray WD40 up into the drawbar mechanism[*] and let it drain out along with any debris.

[*] specifically, aim for the gap between the draw cage and the taper’s ball race - it’s the ball race you want to clean

Ok, makes sense. Thanks for the help.

What do you think of the video? I posted it so the CNCDepot.net folks could see what I am talking about but its part of the video system attached to the machine now. It is for generating the content that is going to be part of my store + subscription model.

It’s actually hard to sync two different video sources that have different frame rates. It also doesn’t help one is wireless and drops frames.

Anyways, I will have to mark this thread as resolved soon and move to the buy and sell topic ![]()

One of my plans is to put a camera on the carriage, but I’d point it down, and use it for “touching off” on a feature. I already have a spare CAT5 up there for it. I’m still at the stage where I watch my robots in person ![]()

I have a 4 port USB 2.0 hub + 60 watts of power up there and I am looking at several two element stereo vision cameras like this one for better resolution in those sorts of operations;

The ATC-10 Carousel fit for the AvidCNC PRO4896 v21.1+

This means your max tool length is about 2 inches or less of stickout. Less if you have stock over the 96 inches in length.

It is really shaping up that the carousel will only give the full work envelop on the PRO60120 machines. On those machines you will get the full 61 in x 121 in work envelop with up to 3.5 inches of stickout.

Here it is fully retracted;

With the embargo lifted and the release of the new spindles from CNCDepot official;

The new CNCDepot RM (30/50/70) line will work with the carousel, no changes.

The dust manifold will require some work but can be adaptable.

The new Autel 5.5mm camera for the dust manifold is just amazing! Much higher resolution and much, much higher frame rate. That and I am replacing the GoPro with a hard mounted Insta360 Link PZT.

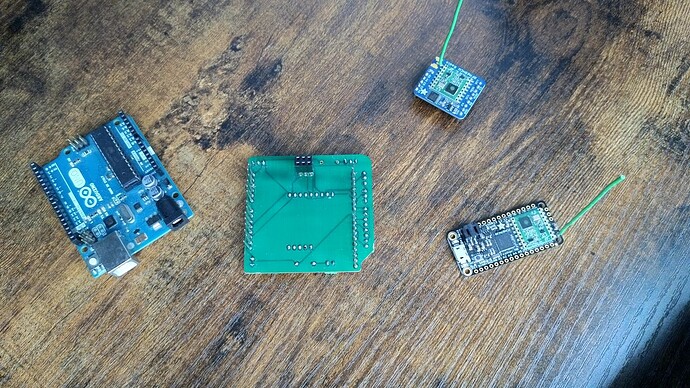

Blast from the past! Here is my custom PCB (cut on my PCB mill, solder masked and assembled by yours truly) and Arduino Uno running Grbl that drove the original carousel.

The communication was via LoRa radio.

Not pictured is the 5v induction sensor for homing and a 5 v pressure sensor for the drawbar line.

This was traditional steppers and ran on 48v using a drone power buck to power the Arduino.

It was in service until the resistor for the pressure sensor fell off. These days I do only surface mount (SMD) designs because of this very PCB. I still do rivets for through PCB connections which is required to make a two layer PCB but this is a single layer board!