avid details.pdf (3.0 MB)

the CNC general specs are listed below

4’x10’ table

CNC Depot Spindle 40 size

EX Controller

Rotary axis

I recently switched over to the ex control and have been having issues with the draw bar actuation. After setting things up, I needed to limp the machine along to finish jobs in the backlog. Now that things have begun to slow down, I need to trace the current problems.

I’ve attached a PDF of the current setup of the machine and the wiring of each box.

1: 1:the case pressure is non-existent and not actuating. It’s my understanding that it’s one of the first G-codes specified on any cut to ensure it runs the entire length of the job.

2: The draw bar currently can only be actuated by a button relay in the program, making things both unsafe and inefficient.

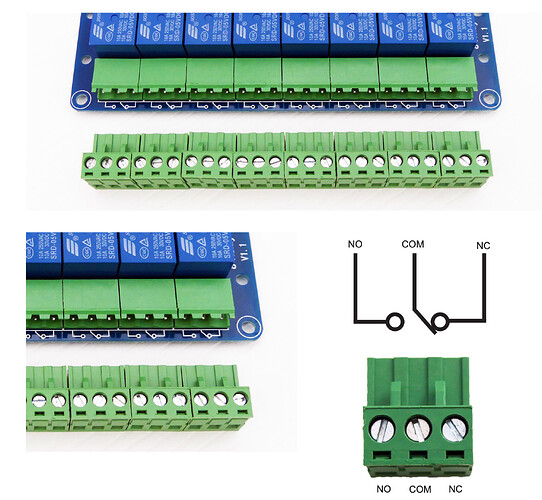

3: I purchased a power relay connected to a single communication wire to enable me to command my compressor and my dust collector. This is pictured in the PDF attached.

4: I’d like to add a manual tool release button that’s either physically mounted to the spindle or elsewhere to make setting up a little easier and give me options down the road.

I’ve seen several threads about fixing the issues I’ve mentioned above; unfortunately, I still cannot seem to fix the issues I am having.

I’ve worked with the AVID team across the board, and I’ve also been working with Alex from CNC Depot to fix these problems. Everyone has been phenomenal to work with.

I just wanted to see if anyone could offer advice on anything I’m not seeing or simple fixes that could alleviate my current dilemma.

thanks in advance.