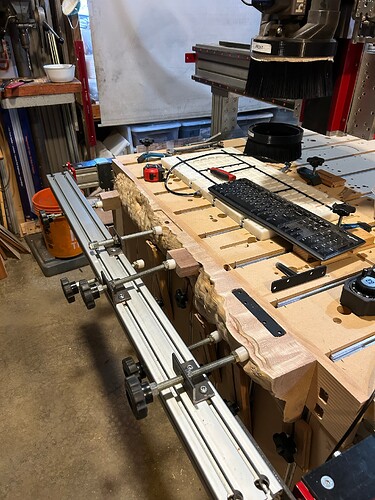

I have yet to design my vertical spoil board [SB] which will most likely be different from the top SB.

I decided to use 1 layer MDF with dovetail slots to use MicroJig products and/or custom hold down clamps not shown in the pics.

I utilize short segments that are made to be modular throughout my SB.

A Z-Zero corner block that has a recessed pocket for the plate to “freely” nest so I can zero material thicknesses down to 3/8”.

I then strategized the usage of 2 different lengths of straight sections to be used to help keeping materials aligned properly.

This is LEGO block approach to start with - for now. It will keep evolving over time.

I have provided the links for the “no pecking required” drill bit and the brass dowel pins below.

They are a perfect fit. No allowance required for hole/pin fit.

[ttps://idcwoodcraft.com/products/extreme-performance-1-4-drill-bit-for-cnc-routers-1-4-shank]