Looking for advice with a rotary job, this is my first time with a rotary CNC but have done plenty of lathe turning. I have searched forums and video tutorials extensively to try to find an answer to my question but so far have come up with nothing.

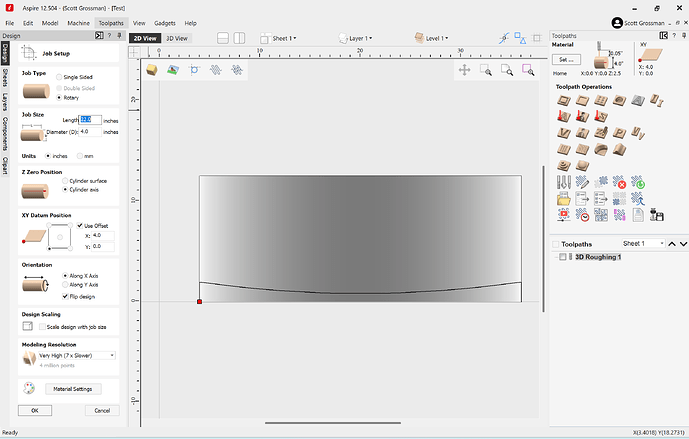

I’m using VCarve Pro 12.5.

I need to produce a dining table leg with a square pommel at the top and round turning for the remainder.

According to Vectric support I need to start with a “rounding tool path”, but to achieve a 4” x 4” square pommel at the top of the leg, I would need to start with a blank of a minimum size of 5.65” X 5.65” (red square) to turn it into a cylinder (blue circle) which could accommodate the 4” X 4” (green square) I am looking for.

To waste 1.65” of material and spend time on machining does not seem like a good business practice.

Or another exaggerated example would be a 1.5” X 1.5” X 36” baluster with a single ½” bead in the middle, to go from square to round to square would a tremendous waste of time and material.

Am I missing something or is there a work around to fool Vcarve and maybe bypass the rounding tool path

Any advice will be greatly appreciated!