Hi! We have a 1/2 CNC 1/2 plasma setup. Want to see if we can plasma cut 12 gauge aluminium. Heard that some water beds are unsuited for cutting aluminium. Just want to double check that the Avid design would not create a problem. Thanks.

@14Acre I cut aluminum on the AVIDcnc set up with a water table, a few times / yr… The primary concern people have is that if one is cutting with the water level all the way up to the bottom of the part, that you might build up a bubble of hydrogen under a larger plate if the plate is cupped upward. My neighbor, around the block, ran a plasma table professionally for years and years and relates to me that it can happen, but it exceedingly rare. He said that if things do go sideways, you do not get an exposionm since there is nowhere for the pressure to build up. Due to the rapidly expansion, one can get a decent slosh water out of the edges of the tank. The effect is omewhere between a woosh and a pop sound as it ‘burps’.

The primary concern is not damage or clean up, but that when / if this happens it can move a full plate of light gauge material while in the middle of a cut by ~1/8in or so.

The way to mitigate it if one is worried about it is to just to leave a small air gap between the bottom of the material and the top of the water level so that there is less resistance, and it will tend to vent.

This issue can happen on any water table (brand-independent) and just tiny mitigation steps can stop it from happening.

Mentioned above, I cut aluminum plates on my water table a few times each year and haven’t had the issue present itself yet.

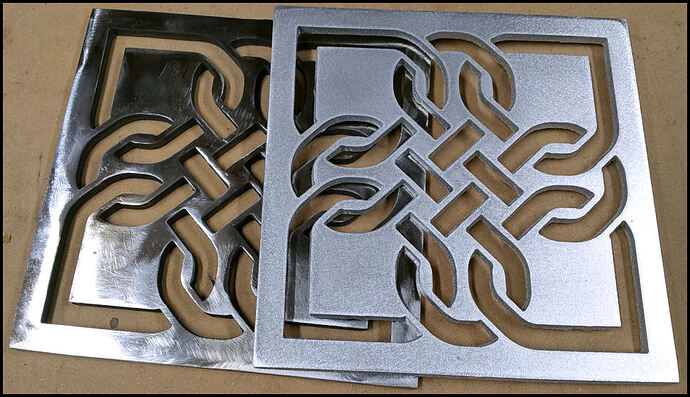

Bottom one is 1/4in Steel, top one is 1/4in aluminum.

1/4in Enclosure side panels: (6061)

~1/8in Additional larger enclosure parts: (6061)

Smaller parts 1/4in:

Enclosure parts 1/8in:

Enclosure parts 1/6in (recycling old material, probably 5052, but unknown):

Upside down 1/8" aluminum diamond plate:

~3/16in pieces for later welding project.

These are just a small subset of the many, aluminum pieces I put through the AVIDcnc plasma table, but it gives you and idea. I cut way more steel and stainless than I do aluminum with it, but all in all it works quite well and I haven’t had any issues. That being said, I am mindful of the issue mentioned at the top, so that I don’t mess up a larger / expensive piece of material.

Very cool. Thank you so much!