Hello! I’m not a total noob, but I’m new Mach4 for sure.

Just got my new PRO4896 up and running. I ran the Vectric squaring and tramming file and the machine is dead on square. Pretty sweet. Coming from an X-Carve…this machine is quite the improvement and I’m super excited to party.

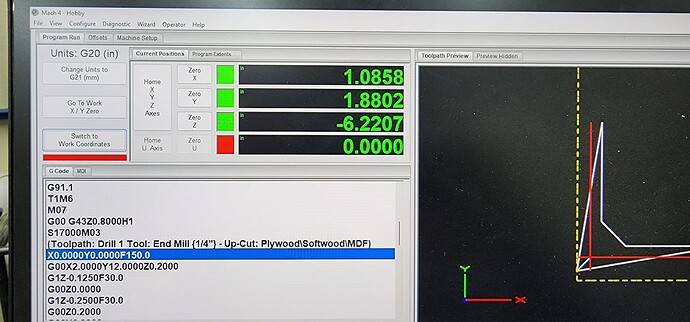

I have a 36"x 36" sheet of 3/4" MDF secured to the machine as a temporary wasteboard and I drew up a simple program to drill some 1/4" holes for some alignment dowel pins. My material setup in Vectric looks good. I homed the machine and then used the touch plate to set my material X,Y,Z…However, when I run the G-Code it fails on line 23 with “Error X Axis commanded over Soft Min”

Is it actually failing on line 24 and Mach just shows the last line ran? I’m guessing it’s failing on line 24. Either way…I have no idea why it’s failing with that error.

23 X0.0000Y0.0000F150.0

24 G00X2.0000Y12.0000Z0.2000

I looked and I don’t have a “Soft Min” set for X which further confuses me. I’d get this error if I DID have a soft minimum set.

( WasteBoardHoles )

( File created: Sunday November 06 2022 - 03:52 PM)

( for Avid CNC Machines, post processor v3.0 )

( Material Size: X= 36.000, Y= 36.000, Z= 0.750)

( Z Origin for Material = Material Surface)

( XY Origin for Material = Bottom Left Corner)

( Min Program Extents: X= 0.000, Y= 0.000, Z= -0.750)

( Max Program Extents: X= 36.000, Y= 36.000, Z= 0.000)

( Home Position: X =X0.0000 Y =Y0.0000 Z =Z0.8000)

( Safe Z = Z0.2000)

()

(Toolpaths used in this file:)

(Drill 1)

(Tools used in this file: )

(1 = End Mill {1/4"} - Up-Cut: Plywood\Softwood\MDF)

G00 G94 G20 G17 G90 G40 G49 G80

G91.1

T1M6

M07

G00 G43Z0.8000H1

S17000M03

(Toolpath: Drill 1 Tool: End Mill {1/4"} - Up-Cut: Plywood\Softwood\MDF)

X0.0000Y0.0000F150.0

G00X2.0000Y12.0000Z0.2000

G1Z-0.1250F30.0

G00Z0.0000

G1Z-0.2500F30.0

G00Z0.2000

G00Y6.0000

G1Z-0.1250F30.0

G00Z0.0000