Good questions.

The first question is what do you want to do with your laser? Engrave or cut, what kind of materials, how big/thick of material? Other questions are how much you think you’ll use it, do you want to use the same design package as your router work, so you have the desire/room for another machine in your shop?

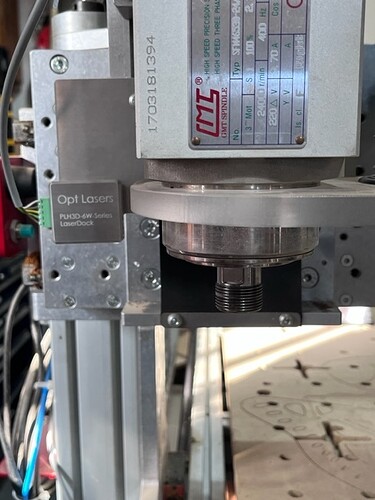

Putting a laser on your AVID gives you a lot more X/Y working area than most dedicated laser machines you are going to buy (unless you are going to spend a lot for a dedicated laser machine). It also gives you a real Z axis (which cheap chinese laser systems don’t have), and a touch probe - these are both critical for getting good focus in a reasonable amount of time for each setup.

You also get to use the same machine you already have, and same software. You just need to install the laser head.

Obviously the downside is that you can’t use the laser and spindle at the same time. It will also not be as fast overall as a well build dedicated machine, but its not that much different because a diode laser (which is probably the only one that makes sense to put on an AVID) is not going to let you run super high speeds anyway.

So what can you do with a diode laser? The two things that matter are power density, and focal length. Current diode lasers have pretty short focal length lenses (30-50mm) compared to CO2 or other types. So the wattage is lower and the beam cone fans out pretty fast. With a good 15W diode laser, you can cut 3mm baltic birch in one pass at about 10ipm feedrate. You can cut really soft woods in a couple passes up to 1/4".

For etching, good diode lasers can have very small focus points, so the power density on the surface is very good, and the blue laser wavelength is asorbed well by some metals compared to CO2 lasers. So for example, an Opt XT-50 laser can ablate the surface of Steel, SS, and Titanium nicely. The 15W laser has a bigger spot size, so not quite enough power density to ablate, but it will melt it so it looks like a 0.006" weld bead. So they mark these metals very nicely. CO2 lasers can’t do this (unless you get a VERY high power one). For high quality pictures, diode lasers are very good because of the small dot size. The XT-50 will burn pixels that are 0.001" to 0.002", which can give you some amazing pictures on tile, slate, metal and organics.

If you want to cut a lot of organics (especially thicker than 0.125"), and working area <3" is ok, I would definitely look into a dedicated CO2 machine.

If you want to do a lot of metal etching, especially deep etching, then a fiber laser with a galvo head is much better.

Now for a good head vs. Chinese ones. The chinese ones typically don’t last too long, especially if you run them at 100% power. However, if you want to just start out cheap to see if its something that will be useful, you can get one and try it out, and then if you use it enough to burn it out, or you decide you want better beam quaility you can buy a better one. An Opt laser vs. a chinese laser head is like the spindle AVID sells vs. using a Harbor Freight Chicgo Electric router. They will both get the job done, but one isn’t going to last as long, or work quite as well. The Opt has machined aluminum housings, a warranty, very good optics, and will typically last a couple 10s of thousands of hours. You can send them back for repair as well. The chinese ones when burned out get thrown away (unless you have the skills to fix it yourself).