My brother and I shopped for quite a while for a gantry machine to support our composites projects, mainly machining foam masters and occasionally trimming finished parts.

Short requirements list:

- 4’x4’ bed

- More than 6" of gantry clearance/Z-travel

- Has to fit through a conventional door

- No steppers

That pretty much sealed the deal for Avid over any other manufacturer.

We ended up buying a used PRO4896. It was “used” in the sense that it had been ordered and delivered to someone else, but never assembled or even removed from the Avid packaging. It’s a newer EX machine with ClearPath servos and a 4HP spindle.

Since we assembled it as a 4848, we needed to off-road a little bit from the included assembly instructions. We also opted to double up on the lateral supports since they came with the machine anyway.

We spent a decent amount of time leveling, squaring, and adjusting the machine before we were happy with the alignment.

We weren’t psyched about only using an MDF sheet as a baseplate as the stiffness and dimensional stability leaves a lot to be desired. After trading some different options we came across a 48"x48"x0.75" sheet of Mic6 aluminum tooling plate from a local scrap dealer. This got counterbored and bolted down. After tweaking the cross beams we ended up with about 0.008" of total height deviation across the entire work surface.

Now that we had a new tool in the shop we started having intrusive thoughts about how to automate some of the more tedious tasks we have in front of us. As mentioned, we’re doing a lot of composites work right now. This includes templating and cutting tons of carbon fiber fabric. We decided to try adding a tangential knife to the machine in support of this.

My brother designed a mount for an additional ClearPath servo motor. The spring-loaded blade holder is made using a ballspline and a 3D printed bearing block. All the other mechanical bits are from McMaster. We’re using the spindle as the toolholder since the ClearPath can’t cope with the axial loads. This has the added benefit of not requiring any additional shafting or X/Y tool offset weirdness. Both the motor and homing switch are wired to the EX controller’s A-axis ports, with power Y-cabled off the X-axis servo. I found a tangential knife post processor for Fusion 360 on GitHub that I re-wrote and customized to work with the Avid. The rotary homing scripts in CNC12 also required some mods to make them work with a C-axis instead of an A-axis.

The crank handle on the left lets us pull the entire assembly as a unit. There’s also a stop collar to index the mount axially and a dowel pin that acts as a rotational stop.

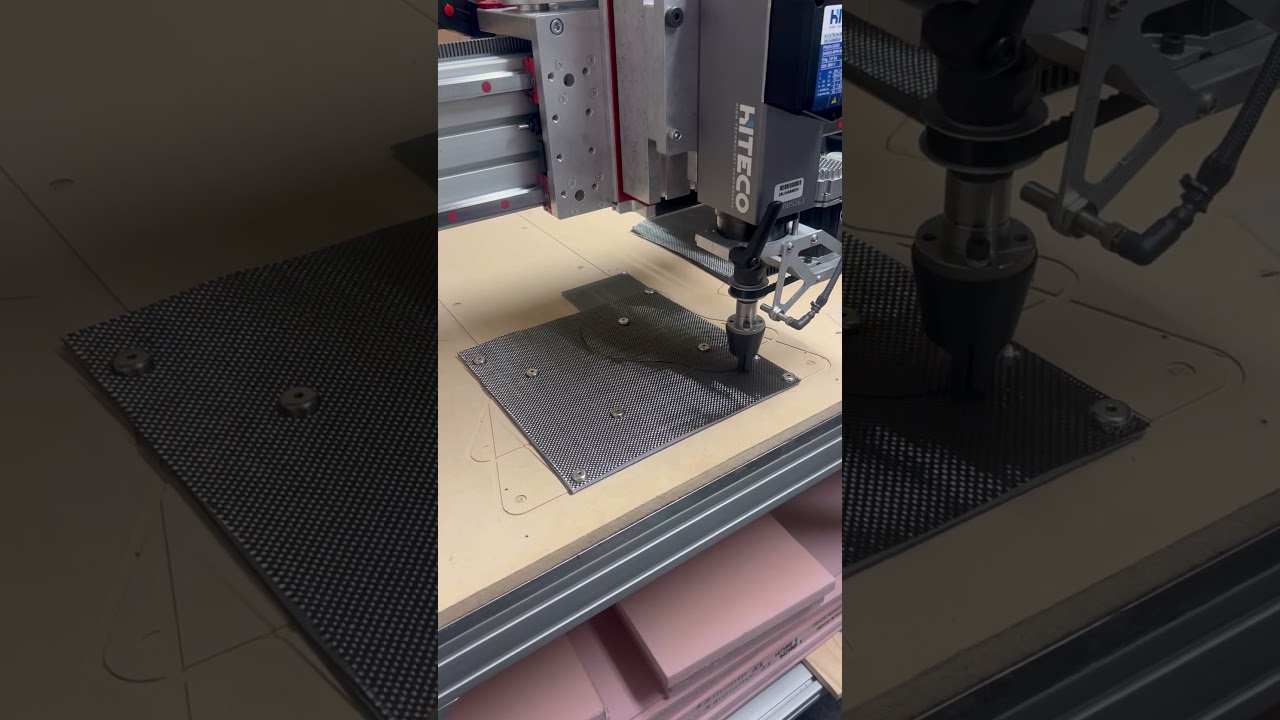

Video of the first test cut:

We have since added a 48"x48"x0.093" LDPE sheet as a cutting surface. That’s backed by a sheet of mild steel. This way we can simply hold the cloth down with magnets.

My only gripe with the machine is how Z-axis and spindle tramming is handled. I think Avid missed the mark a bit on this. The assembly manual mentions nothing about Z-axis tramming, there’s no effective means of adjusting spindle nod, the tilt adjustment is finicky, and moving the spindle up or down on the Z-carriage means you have to re-tram the entire spindle (making the base spindle mount alignment dowels largely useless).

I want to be clear that overall we’re very happy with the machine and the more or less open nature of it’s design lends itself well to customization. We’re excited to keep putting this thing to work.